July 30, 2024 Mitsubishi Electric Europe

Mitsubishi Electric has partnered with HAL Robotics to expand the deployment of operator-controlled industrial robots capable of performing variable, complex and unusual tasks and applications.

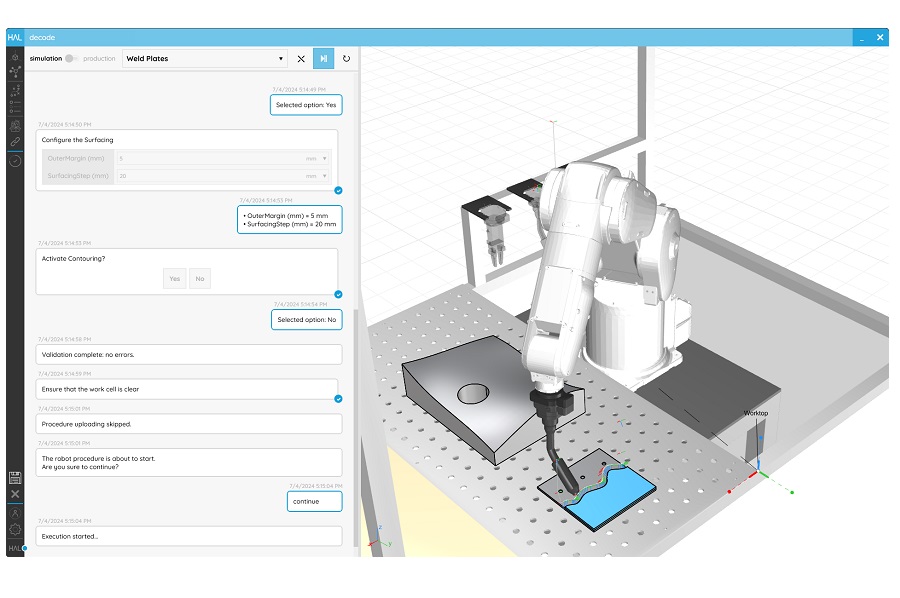

Founded in 2014, HAL Robotics recently released its “Decode” software, which was developed to enable operators or people with specialist process knowledge to adapt robot tasks without the need for programming.

Based on the HAL Robotics Framework, the tool provides system integrators and robot users with the means to set up complex robot toolpaths, simulate and verify procedures, and automatically send programs to the robot for execution. As a result, “Decode” helps eliminate difficult-to-automate, diverse and tedious tasks that previously required continuous human input.

HAL Robotics has partnered with Mitsubishi Electric to enable software integration into the company’s range of small 6-axis MELFA industrial robots, enabling participants across industries to automate non-uniform tasks without the extensive setup and training investments typically associated with bespoke solutions.

Sebastian Andraos, CEO and co-founder of HAL Robotics, commented: “Automation has traditionally been associated with repeatable applications. In contrast, many manufacturing tasks that require intricate manipulation of parts or non-uniform results are often deemed too complex to be performed by industrial robots. Our ‘Decode’ software aims to overturn this assumption.”

“Giving operators the opportunity to quickly modify processes to fit the nuances of individual applications reduces reliance on integrator input. Our new partnership with Mitsubishi Electric will increase access to automation technology, helping to close the skills gap often found on factory floors regardless of industry.”

Barry Weller, mechatronics product manager at Mitsubishi Electric Automation Systems UK, commented: “The importance of HAL Robotics’ ‘decode’ software cannot be underestimated. Enabling operators to more easily integrate human experience and industry knowledge into key processes and non-uniform manufacturing is key to improving efficiency for end users, particularly given the skills shortage affecting the manufacturing industry. We are excited about the future for HAL Robotics and look forward to seeing how their ‘decode’ software is implemented across multiple sectors.”

For more information on HAL Robotics and Mitsubishi Electric’s MELFA industrial robots, visit hal-robotics.com and gb.mitsubishielectric.com/fa/products/rbt/robot.

Request free information from suppliers about the products featured in this article

Log in or register

Process and Control Today is not responsible for the content of any submitted articles or externally produced articles or images. To report an error or omission in this article by email, click here.