When you envision the future of wearables and robotics, foam couch cushions might not be what immediately springs to mind. But Rice University engineers have demonstrated that airflow through the mesh-like structure of open-cell foam could enable digital computation, analog sensing, and combined digital and analog control in a soft, textile-based wearable system.

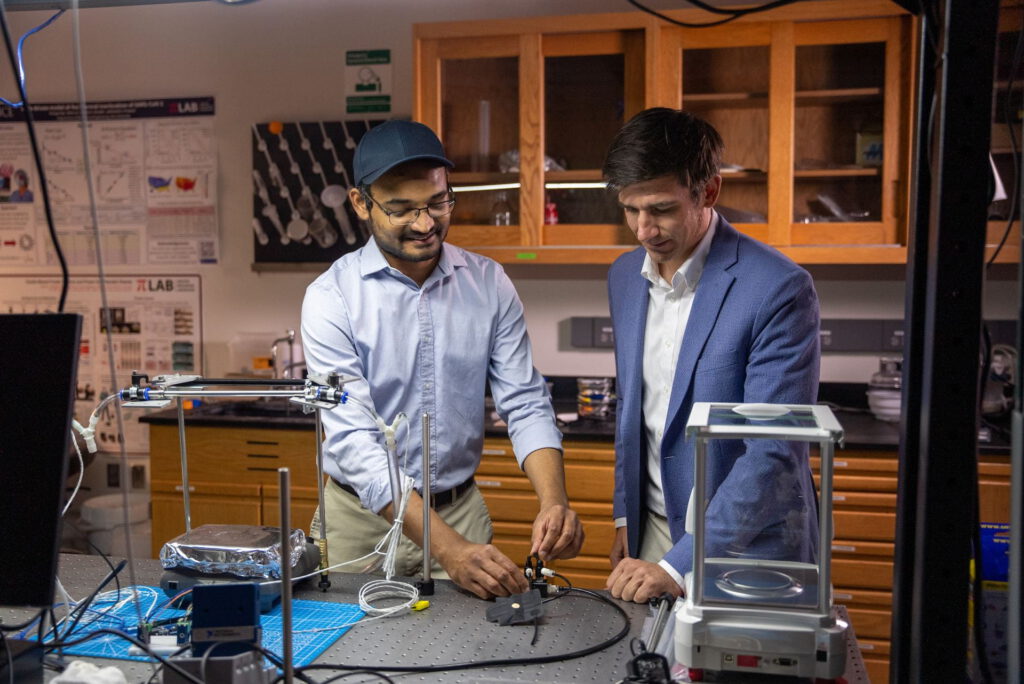

“In this work, we have integrated materials intelligence – the ability of a material to sense and respond to its environment – with circuit-driven logic using a surprisingly simple approach based on the flow of fluid through a soft foam,” said Daniel Preston, assistant professor of mechanical engineering and corresponding author of a paper describing the research published in Advanced Functional Materials.

Cross section of a foam-based fluid resistor (left); micrograph of a cross section of a foam sheet (right). Courtesy of Preston Innovation Lab/Rice University

Pneumatic logic circuits in soft robotics and wearable technology are typically designed to mimic electronic circuits, connecting individual components such as resistors, capacitors, diodes, and gates through linking elements. These traditional architectures rely on interconnected logic gates, the fundamental components of digital systems that convert one or more inputs into a single output.

Previously, the Preston Innovation Lab demonstrated how pneumatic logic circuits could be used to control textile wearables without electronics, but this early approach failed to fully exploit the unique properties of soft materials to optimize the efficiency of the circuit design.

“The more complex the task or operation, the more logic gates you typically need,” Preston explained.

A foam-based fluid actuator that activates with the press of a button. Different levels of force produce corresponding levels of actuation. Credit: Preston Innovation Lab/Rice University

In real-world applications, this could lead to the development of devices that are larger, more expensive, more difficult to manufacture, and more prone to failure. To address this problem, researchers have discovered a way to harness the pressure fluctuations generated by air passing through tiny holes in a foam sheet to perform complex pneumatic calculations and control tasks more efficiently, without the need for extensive circuit design.

“Here, we show that the properties of the soft material itself, such as the sponginess and porosity of a foam sheet, can be leveraged to accomplish fluid control tasks such as sensing the amount of force applied by a user and converting a digital pressure signal into an analog signal. This reduces the reliance on fluid logic gates and simplifies operation,” said Anoop Rajappan, lead author of the study and a research scientist at Rice University during the project.

A foam-based fluid actuator controlled through an integrated digital-to-analog converter. Credit: Preston Innovation Lab/Rice University

Modeling the flow of air through a foam sheet is more complicated because, unlike liquids, the density of air changes with pressure, but the researchers met this challenge head-on and overcame it.

“We developed a theoretical framework to analyze gas flow through porous materials, created new experimental techniques to measure the fluid properties of foam, and finally, generated a model of the change in fluid resistance of foam with applied force,” Rajappan said.

Scientists have created a foam-based fluidic resistor, a tool used to regulate the flow of air in pneumatic systems, in the same way that electronic resistors control the flow of electric current in electronic circuits. These resistors can form two-dimensional pneumatic logic circuits that can be integrated into wearable devices made from textiles.

Foam-based fluidic circuits can be used for tactile data transmission. Credit: Preston Innovation Lab/Rice University

“By redesigning circuit components such as resistors to exploit the fluid properties of soft materials such as foam, we can build reliable, streamlined soft robots and wearable devices powered by air pressure that are less reliant on heavy, bulky or rigid components such as motors and batteries,” Lajapan says. “Wearable robotic devices could, for example, assist users with limited mobility. And by creating wearable devices out of textiles and powering them with compressed air, we can make them comfortable, lightweight, low-cost and unobtrusive for users.”

“Our work at Rice makes real contributions across multiple disciplines, and we are pleased that many students trained in our program continue to contribute in academia, industry and even in their own companies,” Preston said.

Journal References:

Anoop Rajappan, Zhen Liu, Te Faye Yap, Rawand M. Rasheed, Daniel J. Preston. Soft open-cell foams for embedded fluid sensing and control. Advanced Functional Materials, 2024; DOI: 10.1002/adfm.202403379

Source link