Automotive and aerospace companies are actively exploring how quantum technologies can improve CFD, digital twins, and more.

The race is on across all industries to develop the systems, from hardware to software, that will power quantum computing innovation. The technology has been in development for decades and has advanced to the point where many companies are testing how quantum computing will impact their engineering.

“It’s not a question of if, but when. We just need to scale up the hardware to get there,” Eric Garcel, head of technical marketing at quantum software company Classiq, told Engineering.com.

From simulation to digital twins, see how quantum computing will impact engineering applications.

Quantum Computing in Automotive and Aerospace

Quantum computing promises compelling advantages over classical computing: the ability to solve previously unsolvable problems, simulate quantum mechanics more accurately, and operate at incredible speeds—but this promise has not yet been realized.

“Quantum computers don’t have any advantages right now,” Garcelle said. “But [part of] “Digital Transformation Roadmap”

(Image: Classiq)

With companies from IBM to Google working to develop more powerful quantum computers, there’s been strong interest from industries ready to use them.Elica Kyoseva, director of quantum algorithm engineering at Nvidia, told Engineering.com that many organizations are already investing in figuring out how they can incorporate larger quantum computers into their engineering workflows.

The automotive and aerospace industries are exploring the use of quantum computing for simulation, material development, battery research, route optimization, and more.

“A very active area of research is enabling digital twins of complex chemical entities, with applications in electric vehicle battery design and other areas of engineering that require advanced materials,” Kyoseva said.

BMW, Volkswagen and Rolls-Royce have already begun testing quantum computing.

BMW conducted trials in collaboration with Nvidia to showcase how Nvidia’s cuQuantum SDK can accelerate quantum circuit simulation and improve generative modeling algorithms. So far, it has reportedly improved training times for quantum generative models. BMW is also working with Classiq to explore how quantum algorithms can optimize mechatronic systems.

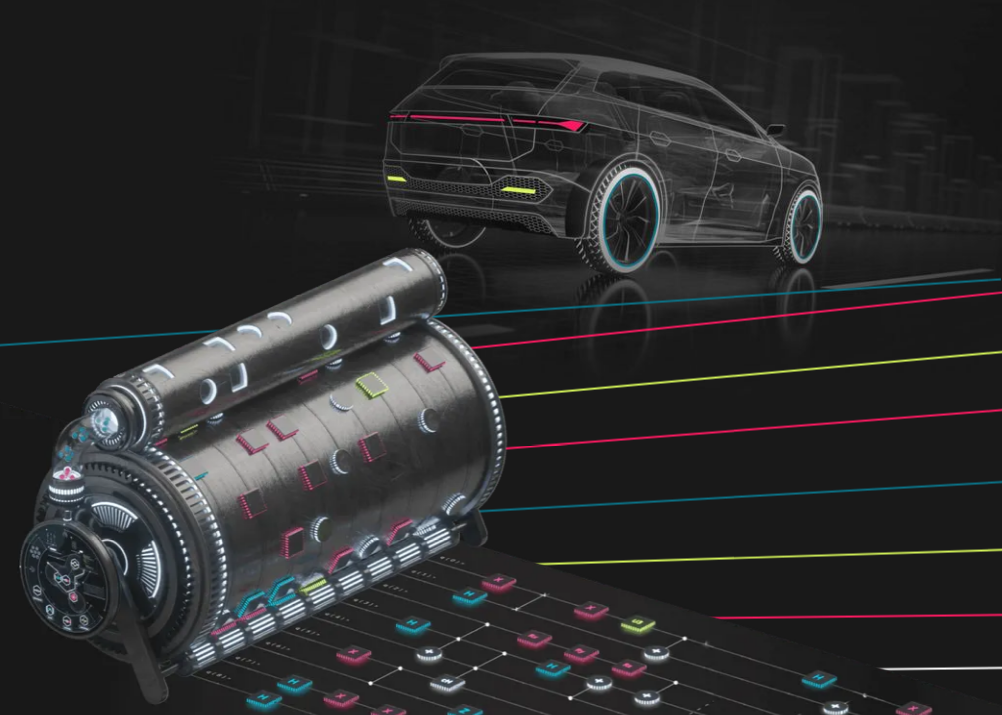

Volkswagen launched a quantum computing research team in 2016. Partnering with quantum providers such as D-Wave and Google, Volkswagen has been exploring various applications of quantum computing in the automotive industry, such as in paint shops. The team developed a quantum algorithm designed to maximize the efficiency of applying different types of primers without slowing down the overall assembly process.

“These challenges may sound simple, but in some cases they require near-supercomputer levels of processing power to be solved with conventional hardware,” David von Doren, Volkswagen’s chief data scientist, said in a company blog post in 2021.

Volkswagen is using D-Wave quantum computers to solve challenges in the automotive industry. (Image: D-Wave Systems)

Last year, Rolls-Royce claimed to have partnered with Nvidia and Classiq to develop “the world’s largest quantum computing circuit for computational fluid dynamics (CFD),” which could help Rolls-Royce more accurately simulate the performance of jet engines.

“The challenge is to get better, more detailed, more accurate simulations,” Garcelle said.

Quantum Digital Twin

Digital twins are another engineering application that can benefit from quantum, as the computing paradigm allows for much more detailed and complex processing in these virtual systems. To advance the technology, Nvidia is also working on creating digital twins of quantum computers themselves.

“Some problems are fundamentally very difficult to solve with classical computers – for example, creating digital twins of complex material simulations or solving large-scale optimization problems including risk analysis, routing and other scheduling tasks. This is really where we feel AI and quantum computing will make a difference,” Kyoseva said.

Garcelle agrees that there will be a big focus on materials once quantum tools catch up.

“It’s easier to simulate quantum mechanics on a quantum computer than it is to simulate it on a classical computer, and that has implications for materials development,” Garcelle said. “How do you create materials that have high strength-to-strength ratios? When you try to figure out how to put these materials together, at some point you have to worry about simulating that quantum mechanics.”

Lowering the quantum barrier

Although there are some big new problems that quantum can overcome, the average engineer probably won’t need to change their daily workflow — at least, that’s Nvidia’s hope.

“it is [engineers] “It takes special care or conscious effort to adapt to this new type of computing,” Kyoseva said.

The software would automatically route computing tasks to the appropriate chip (classical or quantum) and engineers wouldn’t need to be trained on how the chip processes information — they’d just need to see the results.

“Our goal is for this work to permeate every engineer’s workflow, making them more efficient and significantly increasing the throughput of their calculations and simulations,” Kyoseva says, “but at the same time, this is all happening in the background.”

This ease of adoption is what quantum companies are banking on: Companies like Classiq and Nvidia are developing software frameworks and infrastructure to pair with the hardware when it’s ready, and once the technology catches up with their computing ambitions, they want to give users a seamless introduction to incorporating it into their simulations.

The lower barrier to entry already looks promising: “We’re seeing more and more people from different disciplines and fields express interest in exploring quantum computing in their industries,” Kyoseva says. “For my part, I can’t wait to see the full potential of quantum computing realized and transform these industries.”