R, a popular language for statistical analysis, has powerful statistical capabilities that make it suitable for a variety of engineering applications. To explore its fundamental capabilities, this article describes the UR3 CobotOps dataset, donated to the UC Irvine Machine Learning Repository in 2024.

One of R’s biggest selling points is that it is open source. Its strengths in engineering lie in its robust statistical analysis tools, powerful data visualization capabilities, and rich ecosystem of specialized packages. The language also has some limitations in an engineering context. Compared to languages such as MATLAB and Python, it may not be as efficient for large-scale numerical computations, real-time data processing, or complex simulations. Additionally, R’s syntax may not be intuitive for engineers accustomed to traditional programming languages. Please note that the authors’ coding skills are still developing. As a budding R programmer, this analysis relied on the assistance of online tutorials and coding assistance, especially for large language models such as Claude Sonnet 3.5.

Dataset overview

The UR3 CobotOps dataset is a comprehensive collection of multi-dimensional time series data from the UR3 cobot. The UR3, by Universal Robots, is a compact, lightweight collaborative robot arm designed to automate repetitive tasks in a variety of industrial environments. The dataset, which includes 20 features, captures data on operating parameters such as current, temperature, and speed for six joints (J0-J5). It also includes data on gripper current, number of operating cycles, protection stops, and grip loss. The data, collected via MODBUS and RTDE protocols, provides a detailed operating snapshot of the cobot.

Engineering Relevance

This UCI dataset has several potential engineering applications, including:

Fault detection: By analyzing joint current and temperature patterns, engineers can identify potential faults before they lead to failure. Predictive maintenance: Understanding the relationships between operational parameters helps develop predictive maintenance models. Operational optimization: Insights gained from this data can lead to improved control algorithms and more efficient task allocation.

Using R

Now let’s look at how R can help us explore the UCI data for the UR3 cobot. We’ll focus on three main areas: time series analysis, distribution analysis, and correlation analysis.

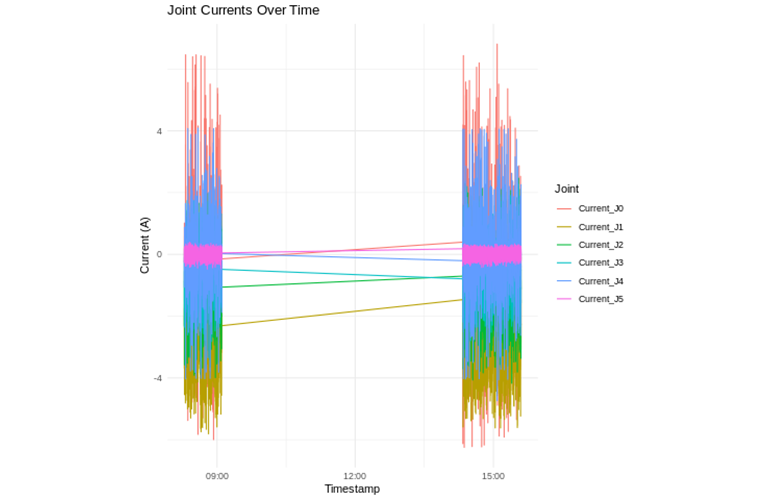

1. Time series analysis of joint current

One of the strengths of R is its ability to effectively process and visualize time series data. We used ggplot2 to create a time series plot of the joint currents. Robot joints (axes) are key components for cobots such as the UR3, allowing rotational or translational motion between connected segments. The UR3 has six joints: the base, shoulder, elbow, and three wrist joints, each providing one degree of freedom. These joints, with the help of motors and sensors, enable the cobot to perform a range of precise movements, generally simulating the versatility of a human arm.

The first graph shows the current (A) through the first joint (here labeled “Joint 0”) over time. Joint 0 is the base joint (the fundamental component of the robot arm), and the time interval between successive timestamps in the dataset is approximately 1 second.

The image shows the dynamic movement of each joint over time, with clear spikes. There are clear patterns of movement, with periods of high activity alternating with periods of relative calm.

Typically, this visualization type helps spot anomalies, reveal patterns of behavior, and detect early signs of wear or failure in specific joints.

2. Distribution of joint temperature

To understand the thermal characteristics of the collaborative robot, we created box plots of the joint temperatures.

The box plot shows the temperatures of different joints, labeled J1 to J5, and the reference temperature sensor, T0.

In our dataset, joints 4 and 5 (J4 and J5) run hotter than the other joints. The cobot manual explains that joints 4 and 5 are part of the wrist. As such, these joints are involved in more complex and precise movements that correlate with increased motor activity and friction.

In general, box plots can help with thermal management, predictive maintenance, and ensuring that cobots operate within safe temperature ranges.

3. Correlation analysis

Correlation heatmaps are useful for understanding the relationships between different operational parameters.

Correlation heatmap of numerical variables for the UR3 cobot dataset. This visualization highlights the strong positive correlation between adjacent joint temperatures (red indicates strong positive correlation) and the negative correlation between some joint currents and their velocities (blue indicates strong negative correlation).

This visualization gives us some insights.

There is a strong positive correlation between the temperatures of adjacent joints. Some joint currents show a negative correlation with the speed. Tool current shows a correlation with various joint parameters.

These visualizations demonstrate the power of R to extract insights from complex engineering data. Such analysis is the foundation for more advanced applications such as predictive maintenance models, fault detection algorithms, and performance optimization strategies.

Additional visualizations

Below are some additional visualizations to give you more insight into the UR3 cobot in action:

This scatter plot shows the relationship between current and speed for joint 0 (base joint) and can reveal the energy consumption pattern of the joint under different operating conditions.

The above histogram shows the distribution of tool current, capturing the typical power consumption of the end effector and potentially identifying different operating modes. For context, an end effector is a device at the end of a robot arm that interacts with the environment, such as a gripper, welder, or other tool used for a specific task.

A time series plot showing the current through the various joints of a UR3 cobot over time. The plot shows the variation in current (in amperes) through each joint.

The bar graph above shows the correlation between different parameters and tool current, helping to identify which factors most strongly influence the end-effector power consumption. This visualization reveals large current variations at all joints, with high amplitudes at joints J0, J1 and J5. As collaborative robots continue to evolve and be integrated into various R&D environments, the ability to extract and interpret such detailed operational data (which is increasingly freely available through open source licenses) may create new opportunities for understanding how robots function.