More than half a century has passed since humans first stepped on the moon, and space missions still require the greatest efforts from many talented engineers. But many of the biggest challenges in space exploration are now a thing of the past, thanks to additive manufacturing.

Companies using 3D printing technology, including Oqton 3DXpert software, have become essential allies in the lunar mission.

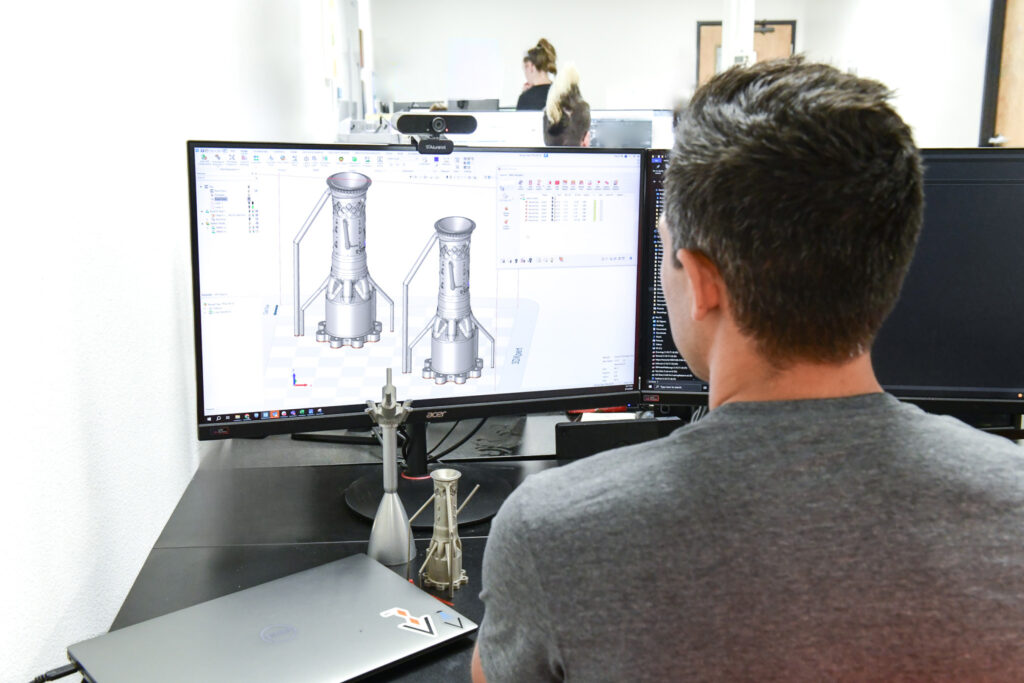

One example is space propulsion solutions provider Agile Space Industries. The US-based company manufactures thrusters and rocket engines, and offers everything from design, 3D printing services, subtractive manufacturing to testing capabilities.

3D printing and propulsion systems are a match made in heaven. “Additive manufacturing opens up endless possibilities in the design space,” says Dustin Crouse, senior additive manufacturing engineer at Agile Space Industries. “This allows us to significantly reduce the mass of our thrusters and rapidly iterate on new designs.”

Space exploration companies like Astrobotic and ispace rely on Agile Space to develop mission-critical parts in record time, going from design and manufacturing to assembly and high-temperature testing in weeks – a process that traditionally took years.

Agile Space Industries creates 3D printed rocket thrusters with the help of 3DXpert. Photo by Oqton.

3DXpert has been crucial to their efficiency. First, the software gives Agile Space full process control. To ensure consistency in production, development engineers lock parameters, limiting the changes that can occur during the production of the thrusters. While production engineers can still move and remove components and update serial numbers, many features are fixed to prevent them from being accidentally changed.

Staying true to the design

Since Agile Space started using 3DXpert, they’ve been able to slice 3D models without converting them to STL files, which has made a big difference. Previously, file conversion was a major operational headache, according to Kyle Metsger, Director of Additive Manufacturing at Agile Space.

Converting a 3D model to STL runs the risk of deviating from the original shape: “Our components have tiny channels, tiny features and critical tolerances. Converting a CAD model to STL creates an approximation of the original shape and introduces variations. We print holes and channels with diameters in the thousands, so dimensional variations are very difficult to control,” explains Metsger.

Features directly impact product performance, so even small deviations can cause big problems. With 3DXpert, Agile Space doesn’t have to deal with such risks.

Since switching to 3DXpert, Agile Space Industries has reduced their total time from build preparation to machining by 60%-70%. Photo by Oqton.

Fast data preparation for complex geometries

Two dramatic improvements Agile Space has experienced since implementing 3DXpert are time to slice and hardware requirements. Their CAD models of components are “powerful” with internal features and high resolution. Complex CAD models result in large STL files.

“When we convert one of our CAD models to STL, it can be over a gigabyte in size. The hardware required for a file of that size gradually increases. We’ve had situations where we’ve had to move the file around in our data preparation software and it has taken 20 minutes to load,” says Metsger.

When the company 3D printed a 4-inch thruster injector component without 3DXpert, data preparation took 14 hours and resulted in deviations in the STL file of 1 to 5 microns, depending on the resolution.

3DXpert allows Metsger to slice native CAD models, resulting in significantly smaller RAM requirements.

This had a major impact on their workflow. “Previously, we would prepare the data during the week and leave the computer running overnight to slice the files. We couldn’t print the parts the same day. With 3DXpert, our overall time from build preparation to machining has been reduced by 60-70%,” adds Metsger.

These time savings are just the beginning: Agile Space and the 3DXpert team continue to work together to rapidly develop and implement new features that will solidify their position at the forefront of the space industry.

The aerospace industry is a huge beneficiary of additive manufacturing. Photo by Oqton.

Read the white paper, “Additive Manufacturing in Aerospace” to learn how other aerospace companies are using additive manufacturing and 3DXpert to push the boundaries of traditional manufacturing and further improve performance.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join our expert panel today.

What does the future hold for 3D printing?

What short-term 3D printing trends are industry experts watching?

Subscribe to the 3D printing industry newsletter to get the latest 3D printing news.

You can also follow twitterLike our Facebook page and Subscribe to the 3D Printing Industry YouTube channel for access to even more exclusive content.

Featured image shows Agile Space employees using 3DXpert. Photo by Oqton.